- Home

-

Categories

Agriculture Apparel Beauty & Personal Care Business Services Chemicals Construction & Real Estate Consumer Electronics Electrical Equipment & Supplies Electronic Components, Accessories & Telecommunications Energy Environment Fabric & Textile Raw Material Fabrication Services Fashion Accessories Food & Beverage Furniture Gifts & Crafts Health & Medical Home & Garden Home Appliances Home Textiles Lights & Lighting Luggage, Bags & Cases Machinery Minerals & Metallurgy Office & School Supplies Packaging & Printing Rubber & Plastics Security & Protection Service Equipment Shoes & Accessories Sports & Entertainment Timepieces, Jewelry, Eyewear Tools & Hardware Toys & Hobbies Vehicles & AccessoriesAgricultural Equipment Agricultural Waste Animal Feed Animal Products Beans Fresh Fruit Fresh Vegetables Grain Hemp Herbal Cigars & Cigarettes Mushrooms & Truffles Nuts & Kernels Ornamental Plants Other Agriculture Products Plant & Animal Oil Plant Seeds & Bulbs Timber Raw MaterialsChildrens Clothing Garment & Processing Accessories Infant & Toddlers Clothing Men's Clothing Novelty & Special Use Other Apparel Sportswear Wedding Apparel & Accessories Women's ClothingBaby Care Bath Supplies Beauty Equipment Body Art Breast Care False Eyelashes & Tools Feminine Hygiene Fragrance & Deodorant Hair Care & Styling Hair Extensions & Wigs Makeup Makeup Tools Maternity Care Men's Grooming Nail Supplies Oral Hygiene Other Beauty & Personal Care Products Personal Hygiene Products Sanitary Paper Shaving & Hair Removal Skin Care Skin Care ToolAdvertising Agency Services Assurance Services Auction Brokerage, Intermediary Service Business Travel Services Certification, Inspection & Credit Management Computer & Information Technology Services Construction Services Consulting Corporate Register & Transfer Design Services Education & Training Internet Service Labour & Employment Law Services Leasing Services Logistics Services Other Business Services Passport & Visa Processing Services Project Cooperation Public Relations Services Repairs & Maintenance Research & Development Services Royalties & License Services Supply Chain Management Telecommunication Services Trade Show Services Translation ServicesAdhesives & Sealants Admixture&Additives Agrochemicals Basic Organic Chemicals Biological Chemical Products Catalysts & Chemical Auxiliary Agents Chemical Reagents Coating&Paint Custom Chemical Services Daily Chemicals Flavour & Fragrance Inorganic Chemicals Non-Explosive Demolition Agents Organic Intermediate Other Chemicals Painting & Coating Pigment & Dyestuff Polymer Surface Treatment ChemicalsBalustrades & Handrails Bathroom & Kitchen Building Boards Building Glass Ceilings Corner Guards Countertops,Vanity Tops & Table Tops Curtain Walls & Accessories Decorative Films Door, Window & Accessories Earthwork Products Elevators & Escalators Fireplaces,Stoves Fireproofing Materials Floor Heating Systems & Parts Flooring & Accessories Formwork Heat Insulation Materials HVAC Systems & Parts Ladders & Scaffoldings Masonry Materials Metal Building Materials Mosaics Mouldings Multifunctional Materials Other Construction & Real Estate Plastic Building Materials Real Estate Soundproofing Materials Stairs & Stair Parts Stone Sunrooms & Glass Houses Tiles & Accessories Timber Wallpapers/Wall Coating Waterproofing MaterialsBlockchain Miners Camera, Photo & Accessories Chargers,Batteries & Power Supplies Commonly Used Accessories & Parts Computer Hardware & Software Earphone & Headphone Electronic Cigarettes Electronic Publications Home Audio, Video & Accessories Mobile Phone & Accessories Mobile Phone Parts Other Consumer Electronics Portable Audio, Video & Accessories Presentation Equipment Smart Electronics Speakers & Accessories TV Receivers & Accessories Video Games & AccessoriesBatteries Connectors & Terminals Electrical Instruments Electrical Supplies Generators Industrial Controls Motors Power Supplies Professional Audio, Video & Lighting Solar Energy Products Switches Wires, Cables & Cable Assemblies Wiring AccessoriesAcoustic Components Amplifiers and Comparators Capacitors Connectors and Accessories Crystals, Oscillators and Resonators Development Systems Diodes, Transistors and Thyristors Displays, Signage and Optoelectronics EL Products Electronic Accessories & Supplies Electronic Data Systems Electronic Signs Electronics Stocks Filters Inductors Integrated Circuits Microcontrollers, Standard and Specialty Optoelectronic Displays Optoelectronics Other Electronic Components PCB & PCBA Potentiometers Power Driver Modules Power Supplies and Circuit Protection Relay Resistors Sensors Switches Telecommunications Wireless & IoTBiodiesel Biogas Charcoal Coal Coal Gas Coke Fuel Crude Oil Industrial Fuel Natural Gas Other Energy Related Products Petrochemical Products Wood PelletsDown & Feather Fabric Fiber Fur Leather Leather Product Other Textiles & Leather Products Textile Accessories Textile Processing Thread YarnCasting Services Forging Services Machining Services Moulds Other Fabrication Services Sheet Metal FabricationBelt Accessories Belts Ear Muffs Gloves & Mittens Hair Accessories Hats & Caps Other Fashion Accessories Other Headwear Scarf, Hat & Glove Sets Scarves & Shawls Ties & AccessoriesBaby Food Baked Goods Bean Products Beverage Canned Food Confectionery Dairy Products Egg Products Escargot Food Ingredients Frog Fruit & Vegetable Products Grain Products Honey & Honey Products Instant Food Meat & Poultry Other Food & Beverage Seafood Seasonings & Condiments SnacksCommercial Furniture Furniture Accessories(new) Furniture Hardware Furniture Parts Home Furniture Kid's Furniture Other Furniture Outdoor FurnitureCandle Holders Candles Crafts Decorative Flowers & Wreaths Festive & Party Supplies Flags, Banners & Accessories Frame Incense & Incense Burners Key Chains Lanyard Money Boxes Music Boxes Other Gifts & Crafts Paintings Photo Albums Promotional & Business Gifts StickersAnimal & Veterinary Chinese Medicine Extract Health Care Products Household Medical Devices Medical Consumables Medicine Pharmaceutical Professional Medical Devices Sex ProductsBaby Supplies & Products Bathroom Products Garden Supplies Home Decor Home Storage & Organization Household Cleaning Tools & Accessories Household Scales Household Sundries Kitchen & Tabletop Lighters & Smoking Accessories Pet Products Rain Gear Smart Home-ImprovementAir Conditioning Appliances Hand Dryers Home Appliance Parts Home Appliances Stocks Home Heaters Laundry Appliances Major Kitchen Appliances Other Home Appliances Personal Care & Beauty Appliances Refrigerators & Freezers Small Kitchen Appliances UV and Ultrasonic Cleaning Appliances Vacuum Cleaners & Floor Care Water Heaters Water Treatment Appliances Wet Towel DispensersBedding Bedding Basics Carpets & Rugs Curtain Cushion Kids & Baby Bedding Other Home Textile Pillows & Cushions Table Linens TowelsCommercial & Industrial Lighting Holiday Lighting Indoor Lighting Landscape Lighting Lighting Accessories Lighting Bulbs & Tubes Other Lights & Lighting Products Outdoor Lighting Professional LightingBackpacks Bag & Luggage Making Materials Bag Parts & Accessories Briefcases Business Bags & Cases Evening Bags Handbags Handbags & Messenger Bags Luggage & Travel Bags Luggage Cart Messenger Bags Other Luggage, Bags & Cases Special Purpose Bags & Cases Sports & Leisure Bags Waist Bags Wallets & HoldersAgriculture Machinery & Equipment Air-Compressors & Parts Apparel & Textile Machinery Building Material Machinery Chemical & Pharmaceutical Machinery Cleaning Equipment Electric Equipment Making Machinery Electronic Products Machinery Electronics Production Machinery Energy & Mineral Equipment Engineering & Construction Machinery Environmental Machinery Food & Beverage Machinery Home Product Making Machinery Industrial Robots Industry Laser Equipment Machine Tool Equipment Machinery Accessories Machinery Service Material Handling Equipment Metal & Metallurgy Machinery Other Machinery & Industry Equipment Packaging Machine Paper Production Machinery Plastic & Rubber Processing Machinery Printing Machine Refrigeration & Heat Exchange Equipment Tobacco & Cigarette Machinery Welding Equipment Woodworking MachineryAluminum Barbed Wire Billets Carbon Cemented Carbide Ceramic Fiber Products Ceramics Copper Fiber Products Fiberglass Products Glass Graphite Products Ingots Iron Lead Lime Magnetic Materials Metal Scrap Metal Slabs Mineral Wool Molybdenum Nickel Non-Metallic Mineral Deposit Ore Other Metals & Metal Products Other Non-Metallic Minerals & Products Pig Iron Quartz Products Rare Earth & Products Refractory Steel Titanium Tungsten Wire Mesh ZincArt Supplies Badge Holder & Accessories Board Board Eraser Book Cover Books Calculator Calendar Clipboard Correction Supplies Desk Organizer Drafting Supplies Easels Education Supplies Electronic Dictionary File Folder Accessories Filing Products Letter Pad / Paper Magazines Map Markers & Highlighters Notebooks & Writing Pads Office Adhesives & Tapes Office Binding Supplies Office Cutting Supplies Office Equipment Office Paper Other Office & School Supplies Paper Envelopes Pencil Cases & Bags Pencil Sharpeners Pencils Pens Printer Supplies Stamps Stationery Set Stencils Writing Accessories Yellow PageBiodegradable Packaging Drug Packaging Gift Ribbon Glass Packaging Handles Logistics Packaging Metal Packaging Other Packaging Products Packaging Auxiliary Materials Packaging Design Packaging Rope Paper Packaging Plastic Packaging Printing Materials Printing Services Pulp Textile Packaging Wooden & Bamboo PackagingPlastic Products Plastic Projects Plastic Raw Materials Plastic Stocks Recycled Plastic Recycled Rubber Rubber Products Rubber Projects Rubber Raw Materials Rubber StocksAccess Control Systems & Products Alarm CCTV Products Firefighting Supplies Locks & Keys Other Security & Protection Products Personal Protective Equipment Police & Military Supplies Roadway Safety Safes Security Services Self Defense Supplies Water Safety ProductsAdvertising Equipment Cargo & Storage Equipment Commercial Laundry Equipment Financial Equipment Funeral Supplies Other Service Equipment Restaurant & Hotel Supplies Store & Supermarket Supplies Trade Show Equipment Vending Machines Wedding SuppliesFunctional Shoes Kids Shoes Men Shoes Other Shoes Outdoor Shoes Shoe Care & Services Shoe Materials Shoe Parts & Accessories Shoes Stock Women ShoesAmusement Park Artificial Grass & Sports Flooring Boats & Ships Cycling Fitness & Body Building Gambling Golf Indoor Sports Musical Instruments Other Sports & Entertainment Products Outdoor Sports Racquet Sports RVs & Campers Souvenirs Sports Bags Sports Safety Sports Shoes Team Sports Trade Show Tent Water Sports Winter SportsAbrasives Bearing Accessories Bearings Drill Bits Fasteners HVAC Hydraulic Tools Lab Supplies Machining Material Handling Tools Measuring & Gauging Tools Other Tool Pipe Fittings Pneumatic Tools Power Tool Accessory Power Tools Power Transmission Parts Pumps & Parts Test Instruments Testing Equipment Tool Parts Tool Sets Tool Storage Valve Welding & Soldering Supplies Hand Tools HardwareAction Figure Baby Toys Balloons Candy Toys Classic Toys Dolls Educational Toys Electronic Pets Fishing Toys Glass Marbles Light-Up Toys Noise Maker Other Toys & Hobbies Outdoor Toys & Structures Pretend Play & Preschool Solar Toys Toy Accessories Toy Animal Toy Guns Toy Parts Toy Robots Toy Vehicle Wind Up ToysATV/UTV Parts & Accessories Automotive Parts & Accessories Aviation Parts & Accessories Bus Parts & Accessories Container Parts & Accessories Go Kart & Kart Racer Parts & Accessories Heavy Duty Vehicle Parts & Accessories Marine Parts & Accessories Motorcycle Parts & Accessories New Energy Vehicle Parts & Accessories Railway Parts & Accessories Trailer Parts & Accessories Train Parts & Accessories Truck Parts & Accessories Universal Parts Vehicles & Transportation

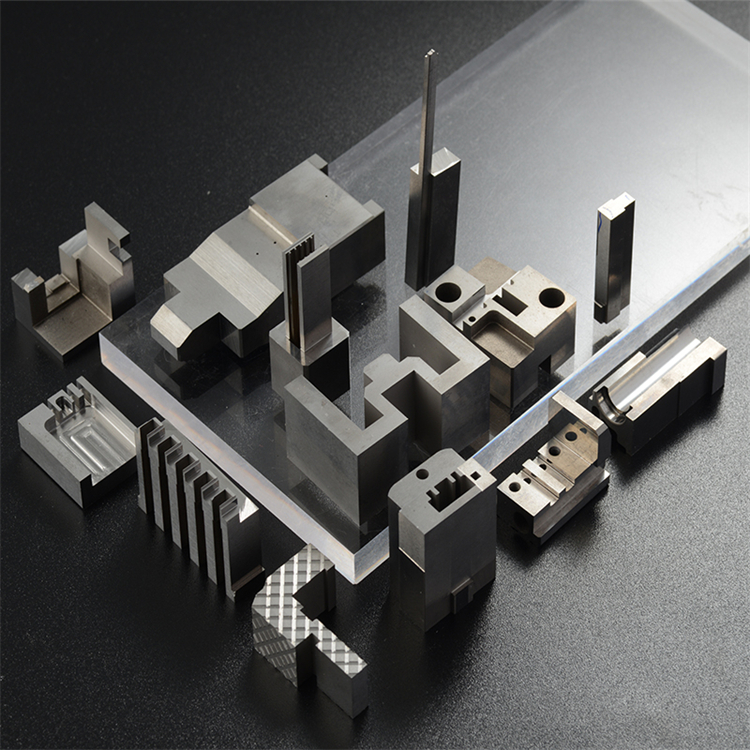

Slow-walk machining of mold parts

Slow-walk machining of mold parts

Slow-walk machining is a technique used for the precise machining of mold parts. In this process, the cutting tool is moved at a very slow speed to remove material from the workpiece gradually. Slow-walk machining is often used for finishing operations, as it allows for high precision and a superior surface finish. The slow movement of the cutting tool during slow-walk machining helps to reduce vibration and chatter that can occur during high-speed machining operations. This results in a smoother surface finish and reduces the risk of damaging the workpiece. Slow-walk machining can be performed using a variety of tools, including milling machines, lathes, and other CNC equipment. The process can be automated using computer-aided manufacturing (CAM) software to ensure consistency and accuracy.